自己紹介・研究目的

令和6年10月入学/ ■SPRING事業 採択学生紹介

生命・物質・エネルギー科学プログラム

令和6年10月 大学院入学

馮 浩哲

ヒョウ コウテツ

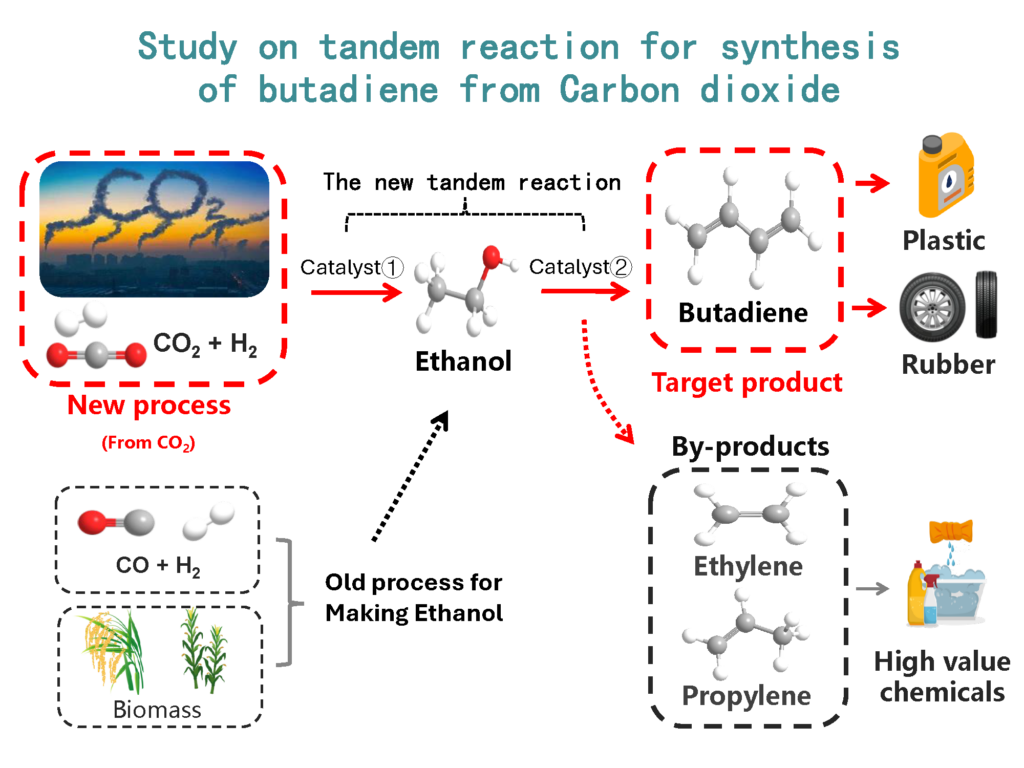

The Study of tandem reactions for the synthesis of butadiene from Carbon dioxide

It is my pride to introduce myself as FENG HAOZHE. I am a first-year doctoral student from Tsubaki Lab who is majoring in Life, Materials, and Energy Science. My research topic is the Study of tandem reactions for the synthesis of butadiene from Carbon dioxide.

Butadiene is an important monomer in producing tires, rubbers, polymers, plastics, resin, and others. More than 95 % of butadiene as a co-product is primarily derived from steam thermal cracking and fluid catalytic cracking of naphtha to ethylene production. However, the recent abundant shale gas as an alternative feedstock for steam thermal cracking mainly produced ethylene with much less butadiene, resulting in a remarkably insufficient butadiene production. Accordingly, the conversion of CO2 to EtOH to butadiene has attracted extensive attention as a renewable alternative route considering both environmental concerns and potential economic opportunity.

Since the direct conversion of carbon dioxide to butadiene is very challenging, there is still very little research on this aspect. By comparing different synthesis pathways, this study first proposed the use of ethanol as an intermediate product; first preparing ethanol by hydrogenating carbon dioxide, and then synthesizing butadiene through ethanol. This problem can be divided into two parts to solve. By developing new catalysts to improve the conversion rate of carbon dioxide in the first part and the conversion rate of ethanol in the second part; by treating the catalyst in different ways to improve the selectivity of butadiene; the yield of carbon dioxide to butadiene can be increased.

Butadiene is an important monomer in producing tires, rubbers, polymers, plastics, resin, and others. More than 95 % of butadiene as a co-product is primarily derived from steam thermal cracking and fluid catalytic cracking of naphtha to ethylene production. However, the recent abundant shale gas as an alternative feedstock for steam thermal cracking mainly produced ethylene with much less butadiene, resulting in a remarkably insufficient butadiene production. Accordingly, the conversion of CO2 to EtOH to butadiene has attracted extensive attention as a renewable alternative route considering both environmental concerns and potential economic opportunity.

Since the direct conversion of carbon dioxide to butadiene is very challenging, there is still very little research on this aspect. By comparing different synthesis pathways, this study first proposed the use of ethanol as an intermediate product; first preparing ethanol by hydrogenating carbon dioxide, and then synthesizing butadiene through ethanol. This problem can be divided into two parts to solve. By developing new catalysts to improve the conversion rate of carbon dioxide in the first part and the conversion rate of ethanol in the second part; by treating the catalyst in different ways to improve the selectivity of butadiene; the yield of carbon dioxide to butadiene can be increased.