自己紹介・研究目的

令和6年度修了/ ■SPRING事業 採択学生紹介

ナノ新機能物質科学専攻

令和6年度 大学院入学

黄 昊

コウ コウ

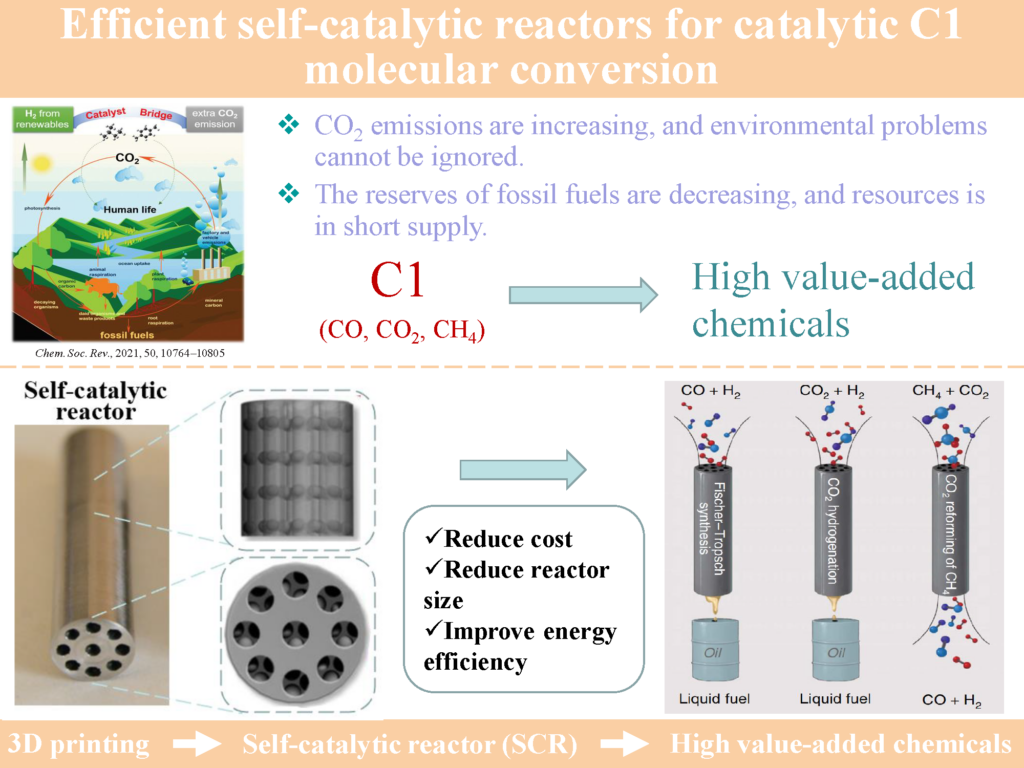

Efficient self-catalytic reactors for catalytic C1 molecular conversion

Hello everyone, my name is Hao Huang. I am a Ph.D. in New Nano and Functional Materials Science from Tsubaki Lab. The content of my research is the catalytic conversion and utilization of C1 molecules. I hope to propose a novel and efficient scheme to realize the conversion of C1 molecules (CO, CO2 and CH4) to high value-added chemicals.

With the dwindling sources of petroleum and the increasingly serious problems of environmental pollution, C1 chemistry has become even more important due to the increasing need for the manufacture of fuels and petrochemical commodities. Catalytic conversion of one-carbon (C1) molecules, such as CO, CO2 and CH4, into fuels and value-added chemicals is a vitally important process in the chemical industry. However, the selectivity control, energy saving, and emission reduction remain great challenges for C1 chemistry due to the complex and change able conversion processes. Three-dimensional (3D) printing has been widely studied in biotechnology, prosthetics, pharmaceutical synthesis, etc. Mechanical properties and geometries of printed products have been extensively studied in metal 3D printing. However, chemical properties and catalytic functions, introduced by metal 3D printing itself, are rarely mentioned. To effectively reduce the operating costs, metal 3D printing is a very promising technology to revolutionize the devices. On this basis, we designed a self-catalytic reactor (SCR) incorporating multiple catalytic functions. The synergy between the catalyst and the reactor is enhanced through metal 3D printing technology, further reducing the cost and reactor size significantly, and improving energy efficiency. Thus, the efficient conversion of C1 molecules can be realized to prepare high value-added liquid fuel, which can solve the energy problem and alleviate the environmental pollution problem. We anticipate that these printing designs will facilitate the further development of 3D printing technology, and spark a technological revolution of traditional chemical industries and machinery manufacturing industries.

(旧フェローシップ事業採択学生)

With the dwindling sources of petroleum and the increasingly serious problems of environmental pollution, C1 chemistry has become even more important due to the increasing need for the manufacture of fuels and petrochemical commodities. Catalytic conversion of one-carbon (C1) molecules, such as CO, CO2 and CH4, into fuels and value-added chemicals is a vitally important process in the chemical industry. However, the selectivity control, energy saving, and emission reduction remain great challenges for C1 chemistry due to the complex and change able conversion processes. Three-dimensional (3D) printing has been widely studied in biotechnology, prosthetics, pharmaceutical synthesis, etc. Mechanical properties and geometries of printed products have been extensively studied in metal 3D printing. However, chemical properties and catalytic functions, introduced by metal 3D printing itself, are rarely mentioned. To effectively reduce the operating costs, metal 3D printing is a very promising technology to revolutionize the devices. On this basis, we designed a self-catalytic reactor (SCR) incorporating multiple catalytic functions. The synergy between the catalyst and the reactor is enhanced through metal 3D printing technology, further reducing the cost and reactor size significantly, and improving energy efficiency. Thus, the efficient conversion of C1 molecules can be realized to prepare high value-added liquid fuel, which can solve the energy problem and alleviate the environmental pollution problem. We anticipate that these printing designs will facilitate the further development of 3D printing technology, and spark a technological revolution of traditional chemical industries and machinery manufacturing industries.

(旧フェローシップ事業採択学生)