自己紹介・研究目的

令和6年度修了/ ■SPRING事業 採択学生紹介

ナノ新機能物質科学専攻

令和6年度 大学院入学

王 鋮偉

オウ チエンイ

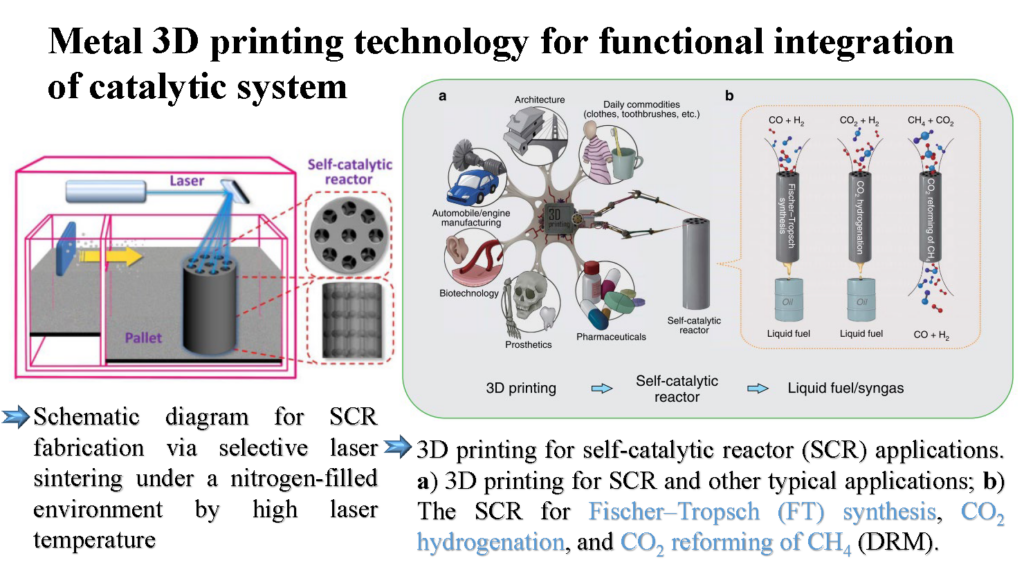

C1化学のための金属製3Dプリント自己触媒反応器

Traditionally, petroleum refining is the main way to produce liquid fuel. But, with rapid depletion of petroleum reserves, it is urgent to develop new synthetic routes for conversion of non-petroleum resources (such as natural gas/shale gas, CO2, biomass) into liquid fuel. Fischer–Tropsch (FT) synthesis, CO2 hydrogenation, and CO2 reforming of CH4 (DRM), as the alternative routes or key steps, have been studied for a long time. But huge operating costs in the conventional plants always prevented them from large-scale industrial applications. To effectively reduce the operating costs, metal 3D printing is a very promising technology to revolutionize the devices. On this basis, our integrated design, that is the printed self-catalytic reactors (SCRs) in combination with various catalytic functions, can further minimize the costs and reactor sizes dramatically, and improve the energy efficiency. The printed metal devices can tolerate high temperatures and high pressures. The metal compositions are natural catalysts to various chemical reactions. Moreover, the precise fabrication via computer-assisted design (CAD) can guarantee high reusability, and eliminate personal errors caused by different workers during the fabrication. We believe that in the future it will stimulate the developments of various 3D printing technologies to manufacture multi-functional devices, and have wide applications in fields of chemistry and chemical engineering.